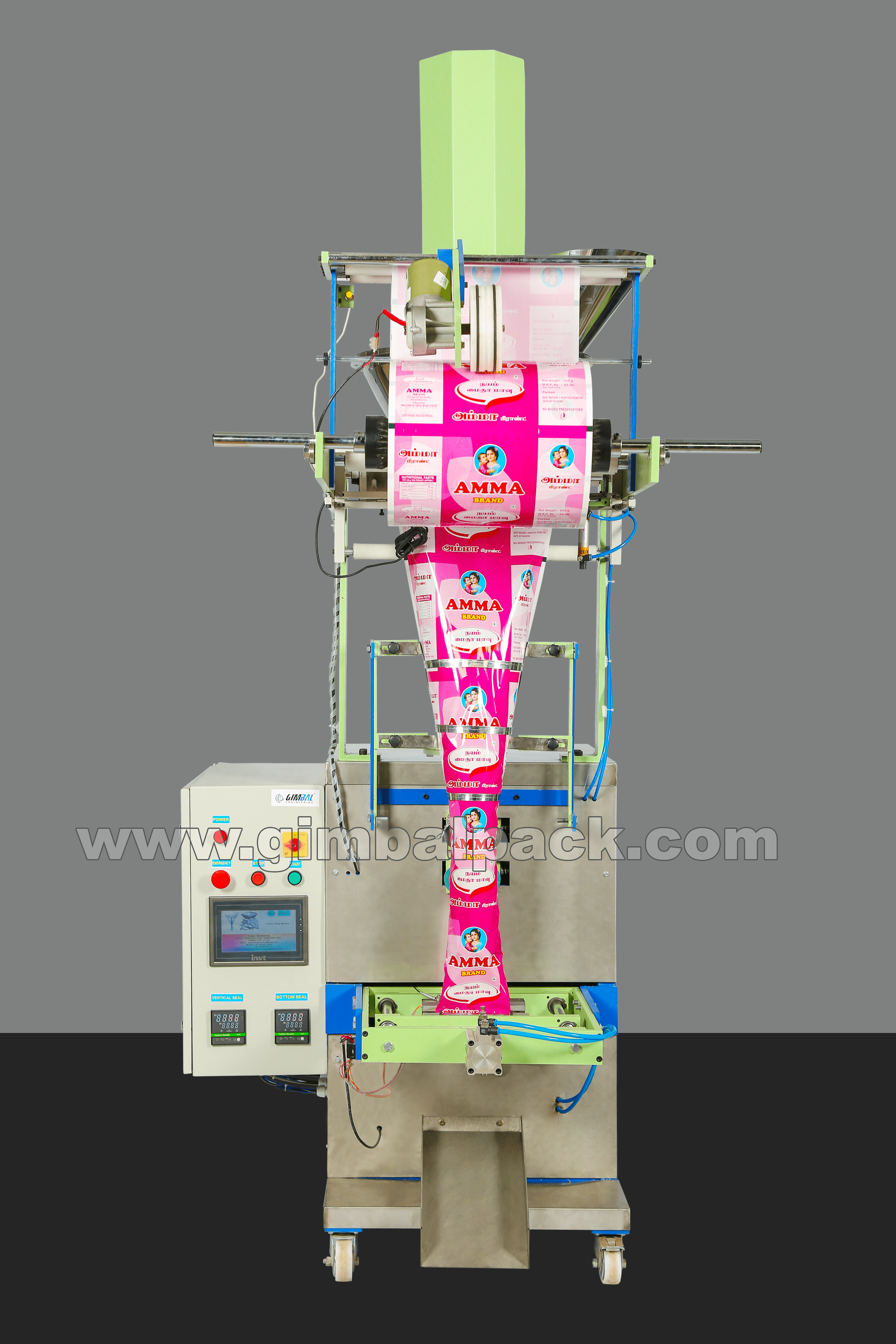

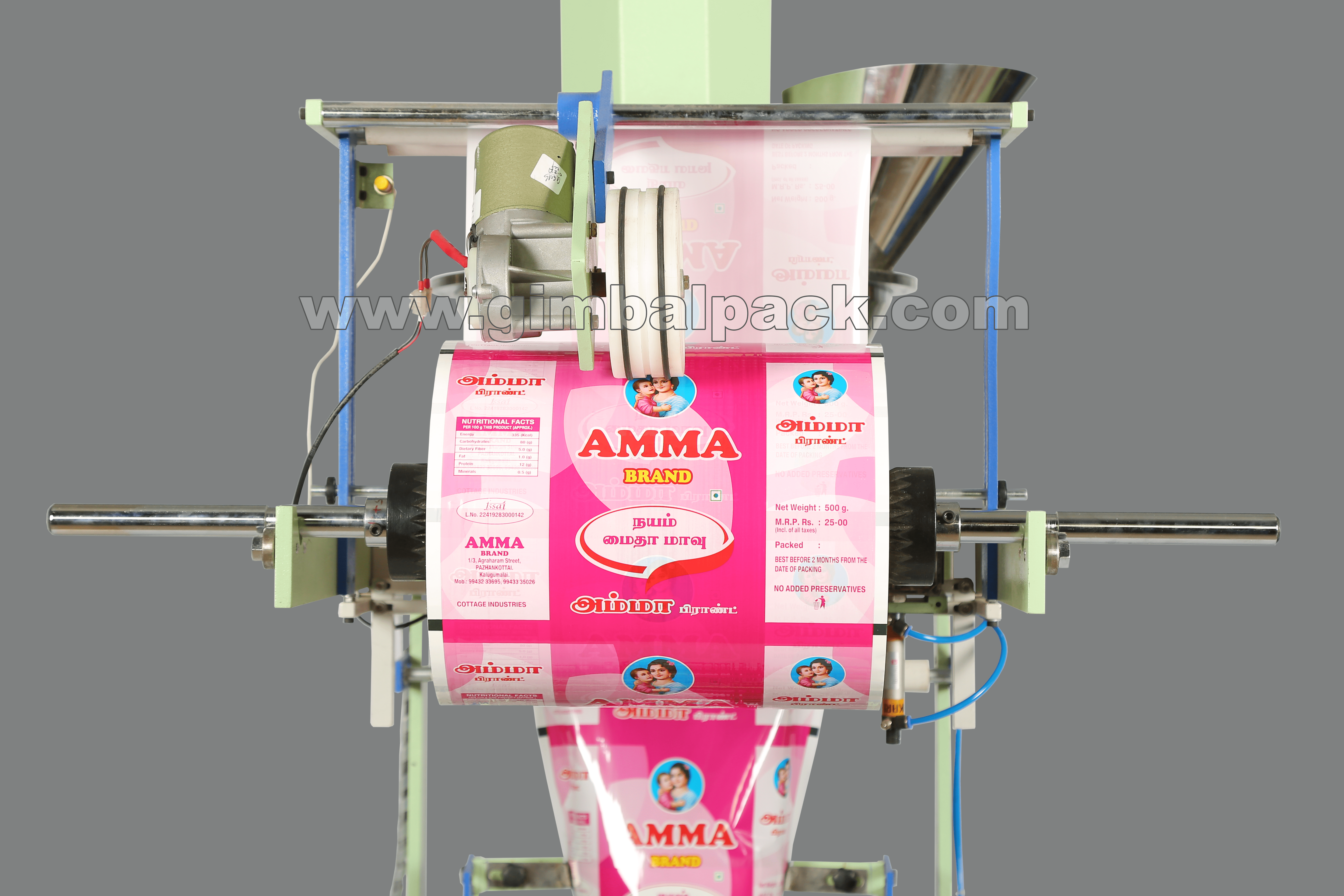

Spices Powder Pouch Packaging Machines

Product Details:

- Material Automatic Powder Packing with all contact parts of SS304, machine Construction Mild Steel with epoxy powder coating outer cover SS202etal

- Feature Rust Proof Heavy Duty Machine Durable Less Power Consumable Highly Efficient

- Capacity 15-30 p/min [Product flow ability and efficiency of operator] Pcs/min

- Computerized Yes

- Automatic Grade Automatic

- Control System PLC Control

- Drive Type Pneumatic

- Click to View more

Spices Powder Pouch Packaging Machines Price And Quantity

- 240000.00 - 350000.00 INR/Unit

- 1 Unit

- 1000000 INR/Unit

Spices Powder Pouch Packaging Machines Product Specifications

- PLC Control

- Other

- 5 Horsepower (HP)

- Yes

- Rust Proof Heavy Duty Machine Durable Less Power Consumable Highly Efficient

- Yes

- Automatic

- 230-240 Volt (v)

- Pneumatic

- Automatic Powder Packing with all contact parts of SS304, machine Construction Mild Steel with epoxy powder coating outer cover SS202etal

- 1900*950*2350 Millimeter (mm)

- 270 Kilograms (kg)

- 15-30 p/min [Product flow ability and efficiency of operator] Pcs/min

Spices Powder Pouch Packaging Machines Trade Information

- 10 Unit Per Month

- 20 Days

- All India

Product Description

With the addition of advanced technology, Gimbal Engineering Company is engaged in manufacturing and supplying qualitative range of the Spices Powder Pouch Packaging Machines.

In this machine we are using PLC based control system and HMI Operating system. Auger filling is used and the pouch feeding will be automatic. In this type, ultrasonic level sensors can be used if it's necessary. The material contact area is SS 304 with the filler hopper capacity of SS 304-30 Liters. Servo motor is used with provided caster wheel or antivibration wheel machine base mounting. The power supply required for this machine is 440V 50Hz Or 230V 50HZ.

In powder filling machine, 25-50 Pouches will be packed per minute with product flow ability and efficiency of operator. The filling range is 1 gm to 1000 gm using help of change parts and filling accuracy will be at +0.5 percentage to +1percentage with constant powder level in the machine hopper and consistency of bulk density